Why Are Vinyl Flake Epoxy Resin Floors So Popular?

Epoxy resin

is a durable polymer that, when mixed with a hardener

, creates the strongest floors on the market. Epoxy

is renowned for its chemical resistance

, heat tolerance

, and impact strength

. It's used in industrial

settings just as much as its used in garages

, and it fits both perfectly!

Your garage should be seamless, easy to clean,

and

strong. Epoxy

's

got it all - and its available in a myriad of colors

and finishes!

While vinyl flake

is the gold standard for

garage flooring

,

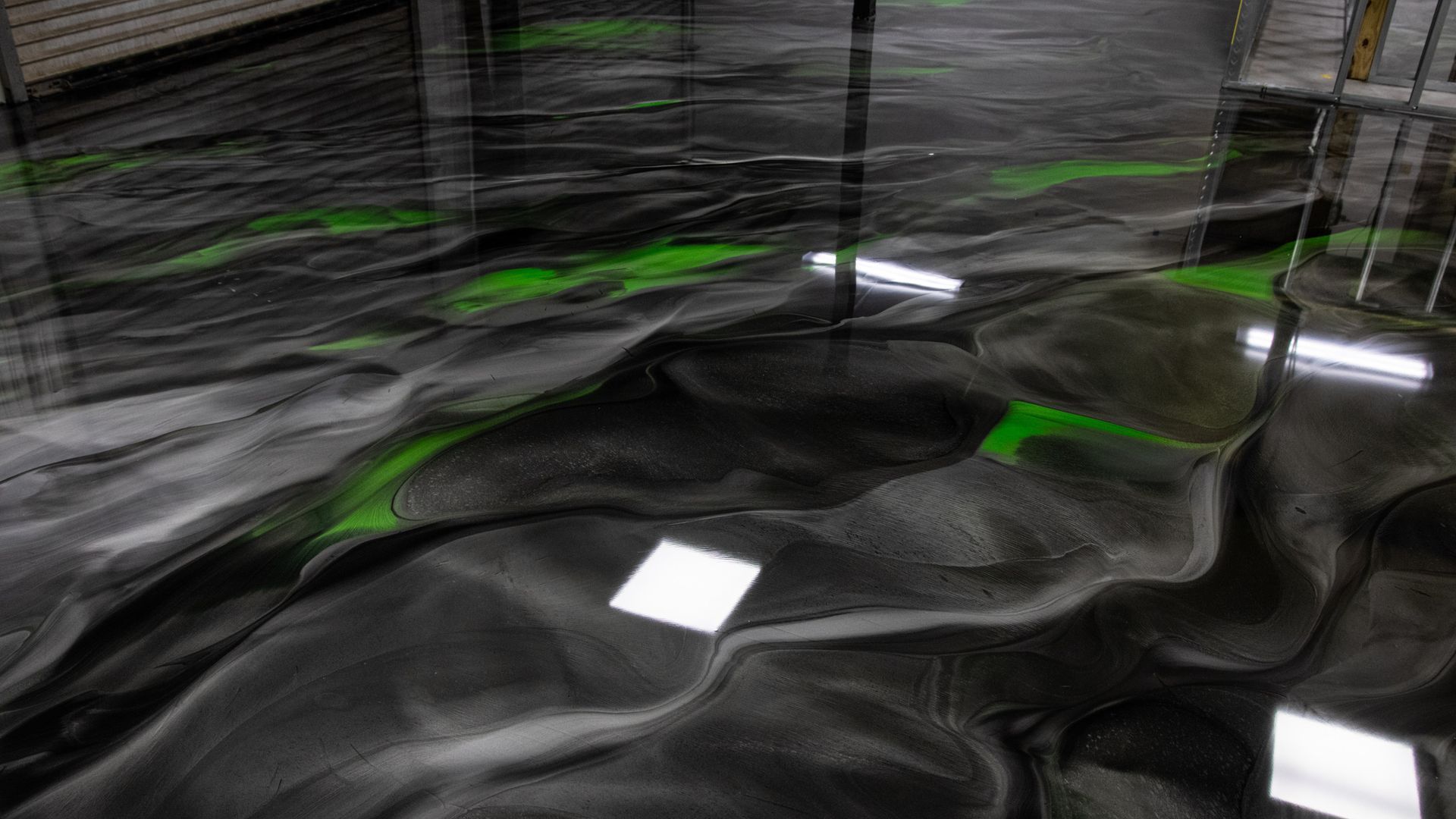

you are far from limited to only that. Go for gold with glitter

or a clean, simple solid color,

or even an intricate metallic epoxy

flooring design!

Essential Tools and Resources

Before embarking on the installation process, ensure you have the following tools and resources:

Step-by-Step Installation Guide

Vinyl flake epoxy resin floors

have become the gold standard

in garage

flooring

not just because of their strength

. They're known for just how easy

& affordable

they are to install, too! Our guide here will provide a basic overview of the steps you need to go through to get that strong garage flooring you want.

For the best results, we recommend contacting a local flooring contractor still. But, if you are DIY-minded

, epoxy resin

floors

are some of the easiest to install on the market!

Step 1:

Surface Preparation

Surface preparation

is one of the most important steps in the whole process, and yet it's too often neglected

or even ignored

during installatio

n. And it's so simple, too, depending on the condition of your concrete foundation.

Every floor will need to be thoroughly cleaned

with a mild cleanser

and degreaser.

But, if your floor is too smooth

or too uneven

,

you may need to break out the grinder

to fully prepare your floor for epoxy resin

. Don't forget to check for moisture

content

, too!

Step 2:

Apply a Primer Layer

Once the floor is prepared and clean, you should apply a base primer

layer

on top of the foundation. This will help you get the most adhesion

& strength

out of your finished epoxy floor

, and it can begin its curing

process as your prepare the rest of the resin system.

Step 3:

Mix the Epoxy Resin & Hardener Solutions

Your preferred epoxy resin flooring kit

should have manufacturer's instructions on the recommended mixing proportions. For most epoxy resin solutions, the ratio is either 2 parts resin

to 1 part hardener,

or 1:1 resin:hardener.

Be sure to check specifically

with your

solution

!

Messing this up can mean you've wasted an entire epoxy resin

kit

with no floor to show for it.

Step 4:

Apply the Epoxy Resin Solution

Don't wait too long between last step and this step! Once you finish mixing your epoxy resin,

it's already begun its curing process. With a polyaspartic solution

,

this means you'll have anywhere from 4-8 hours

to finish installing and applying the resin. With a traditional resin

solution

, that's extended to about 24-48 hour

s.

Use a squeegee

or a spiked roller

& evenly spread the resin

solution across the floor. If you're working with a large floor, work in sections.

Step 5:

Broadcast the Vinyl Flake/Traction Additive

Once you've gotten the epoxy resin solution

on the ground & beginning to cure, you must broadcast your preferred traction additive

. If you're going for vinyl flake epoxy resin floors, broadcast the vinyl flakes

onto the surface for desired aesthetics. Broadcast

a little or a lot, different color

combinations, it's truly up to you.

Your technique should be a scoop-and-sweep

out from a bucket. This will help with ensuring an even coverage,

but it truly is up to you how you want to broadcast.

Step 8:

Apply the Final Epoxy Resin Layer

Much like the layer of resin

before this, you'll need to wait until the previously layer has cured. Break out the squeegee

or other application tool

& spread your final layer of epoxy resin

evenly over the floor area.

This is the layer that's going to be most visible, so make sure to approach it patiently

and carefully!

Step 7:

Let the Epoxy Resin Cure

Once you've applied your final topcoat layer, all that's left to do is leave it alone. For how long will depend on your resin solution

. As mentioned before, polyaspartic resins

will only take an afternoon - 4 to 8 hours - to fully cure. But traditional resins

may take several times longer - 24 to 48 hours.

Conclusion

A new & revived garage floor

doesn't have to be so far away - it may be only a few days work and a little bit of investment away! Whether you're a DIY enthusiast

making home renovations or a professional contractor

expanding their business, this guide will help you get the fundamentals of vinyl flake epoxy floors

for garages down. Install stronger, cleaner

& better looking floors

today!

Xtreme Polishing Systems (XPS)

is here to get you the tools you need to get the job done today. Whether you need on the job advice from our team of technicians at (877) 958-5264

, or the best resources on the market at competitive rates from our online store, we have it.